Punch

The punch is a stamping press. In national production, the stamping process has the advantages of saving materials and energy compared with traditional machining, high efficiency, low technical requirements for operators, and products that cannot be achieved by machining through various mold applications. Its use is more and more extensive.

Stamping production is mainly for sheet metal. Through the mold, it can be used for blanking, punching, forming, deep drawing, dressing, fine punching, shaping, riveting and extrusion, etc., which are widely used in various fields. For example, we use switch sockets, cups, cupboards, dishes, computer cases, and even missile aircraft… There are so many accessories that can be produced through the mold with a punch.

Polisher

Polishing machines, also known as grinders, are often used for mechanical grinding, polishing, and waxing. The working principle is as follows: the motor drives the sponge or the wool polishing disc mounted on the polishing machine to rotate at a high speed, and the polishing disc and the polishing agent cooperate with each other and rub against the surface to be polished, thereby removing the paint surface contamination, the oxide layer, and the shallow mark. purpose. The rotation speed of the polishing disc is generally 1500-3000 r/min, mostly infinitely variable speed, and can be adjusted at any time according to the needs during construction.

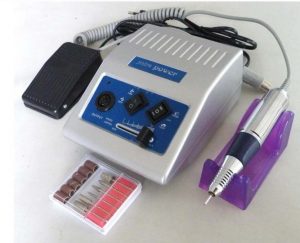

Electric grinder

Introduction

Electric grinder full name reciprocating electric polishing machine (also known as honing machine), widely used in the mold industry for finishing and surface polishing, is a substitute for similar pneumatic products.

Characteristics

- The high-power motor can achieve powerful grinding performance in the whole working range, reaching 150% load;

- Use a complete set of safety solutions: touch-type start, automatic stop, wear-free electronic brake system EBS, quick clamping system QUICKin, power-off reset lock, and soft start;

- Powerful self-supporting motor construction, the switch module is dustproof and durable.

- Use: Remove burrs and sanding.